IFFA-Preview: Grinders, mixer grinders and bowl cutters with the K+G Wetter effect

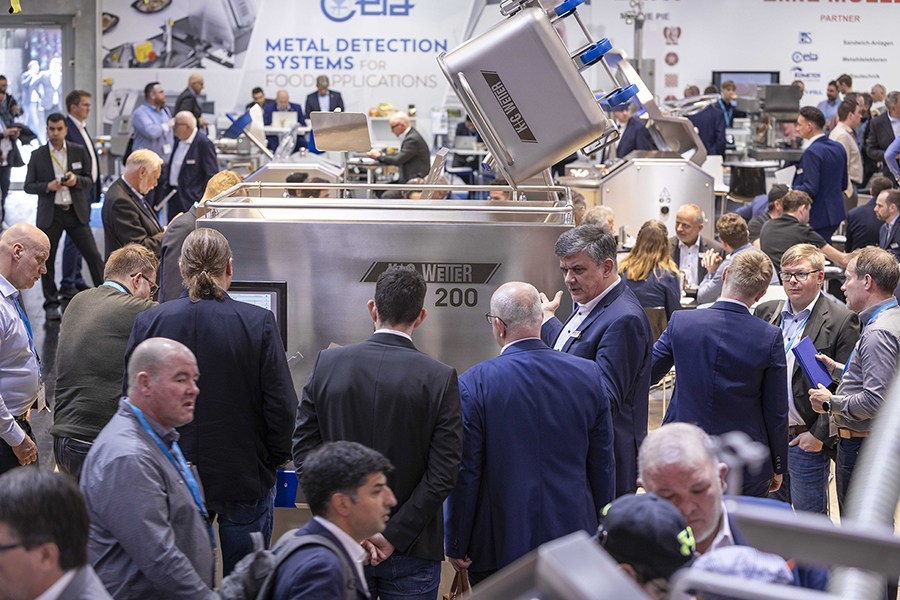

The best technology provides tangible benefits: nothing needlessly slows you down in your daily work in food processing, and what your customers get on their plates tastes good to everyone. K+G Wetter will be demonstrating how this works at IFFA 2025 in Frankfurt. In the ‘World of Processing’ in Hall 8.0 (Stand D96), the meat processing machine specialists will be giving trade visitors from all over the world an insight into their ingenious technical solutions. Anyone looking for new machine technology with a certain K+G Wetter effect – whether for butchers, vegan and vegetarian products, confectionery or pet food – will find plenty of expertise, tips and ideas here in the 450-square-metre area.

Cutters, grinders and mixer grinders from trade to industry

From compact trade cutters to the industrial vacuum cutter VCM 550, the machines from K+G Wetter offer a comprehensive overview of sophisticated vacuum technology, efficient cooking functions and many other clever cutter features for all company sizes. K+G Wetter also offers a wide range of grinders and mixer grinders – from the small EW 114 mm electric grinder, to angle grinders and mixer angle grinders with and without loading, to the AW 280 industrial grinder. The new WW 200 angle grinder will be at IFFA as a flexible all-rounder for fresh and frozen meat blocks.

Clean work

Perfect hygiene is crucial in food production. This makes it all the more important that the machines used can be cleaned quickly and easily – like the bowl cutters of the Hygienic Secure series from K+G Wetter. The new VCM 70 Hygienic Secure shows that the sophisticated features of these machines are not just for large-scale industry: in a compact size for butchers, it is equipped with everything needed to quickly and perfectly clean the cutter after use or before the next batch. Sloping and hand-polished stainless-steel surfaces, parts that can be removed with a flick of the wrist without the need for any tools, such as the patented knife cover strip, the bowl scraper or the large cleaning flaps in the vacuum bowl: Hygienic Secure is well thought out in every detail, saves cleaning time every day and ensures maximum hygiene safety.

Exclusive hygiene feature in the grinders from K+G Wetter: the cleaning chamber. It keeps the machines clean even where you can't otherwise get to for cleaning. The chamber catches everything that could be pushed through the seals of the meat worm into the machine interior due to the enormous pressure during the grinding process. This means that daily flushing through the access from the outside is enough to reliably prevent the formation of germs.

Work more easily and ergonomically

Food production is physically demanding. Clever use of technology makes many work steps easier, creating time and energy to focus on creativity and quality.

Lifting countless full boxes into the cutter bowl or grinder hopper day after day is exhausting, especially in a small-scale business, and the longer you work, the slower you become. The solution from K+G Wetter: the Easy Lift lifting system. Flexible to add to cutters and grinders, it saves hours of work every day and lifts hundreds of kilos.

With the MWW 130 and 160 mixer angle grinders, the Easy Access design also allows uniquely easy accessibility to the grinder hopper: the inside of the hopper can be reached perfectly ergonomically through a large door. The advantage: particularly quick and easy cleaning and easy installation and removal of the meat worm and mixing shaft.

Flexible in use, from vegan to pet food

Even with vegetarian and vegan food, the machines from K+G Wetter have a decisive effect on consistency and flavor. Vacuum cutters, in particular, demonstrate their strengths here: the cooling effect of the vacuum protects the vegetable proteins from denaturing and, due to stronger soaking, longer protein chains are formed. Added to this is the intensification of flavor and improved consistency of the products manufactured in a vacuum, which also have a significantly longer shelf life due to the lower oxygen content.

When it comes to pet food, the grinders from K+G Wetter are in demand: processing raw materials that contain bones and are frozen to -21 degrees presents a major challenge for the machines used. The industrial grinders from K+G Wetter perform these tasks day after day for many hours and thus process tens of thousands of tons of raw materials over many years. An investment that pays off and reliably produces pet food of the best quality.

For focusing on the essentials

Managing recipes, controlling production steps, monitoring and keeping an eye on important parameters: sophisticated software solutions support professionals in food production with features that save time and ensure quality. CutControl for the K+G Wetter bowl cutters stores recipes and processing steps with all important parameters – this is how products of reliably consistent quality are created in a shorter time. CutCounter precisely monitors the number of cuts made by the cutter knives. This is because regular and timely re-sharpening always ensures the desired consistency of the sausage meat. And with the CutVision software from K+G Wetter, food companies can easily and reliably record, document and read out all steps of the production chain.

Think tank IFFA

‘We always develop our machines and software with a view to making the daily work of butchers and other food producers easier, safer and faster,’ summarizes Volker Schlosser. The International Sales Manager at K+G Wetter is therefore looking forward to six days of IFFA trade fair in Frankfurt full of discussions and exchanges with old and new customers and partners. ’Of course we want to sell machines. But exchanging experiences is of course also important to us at a trade fair – where else can you find so much concentrated expertise in such a compact period?’

Photos: K+G Wetter