Thought-out features for more quality and hygiene in food craft

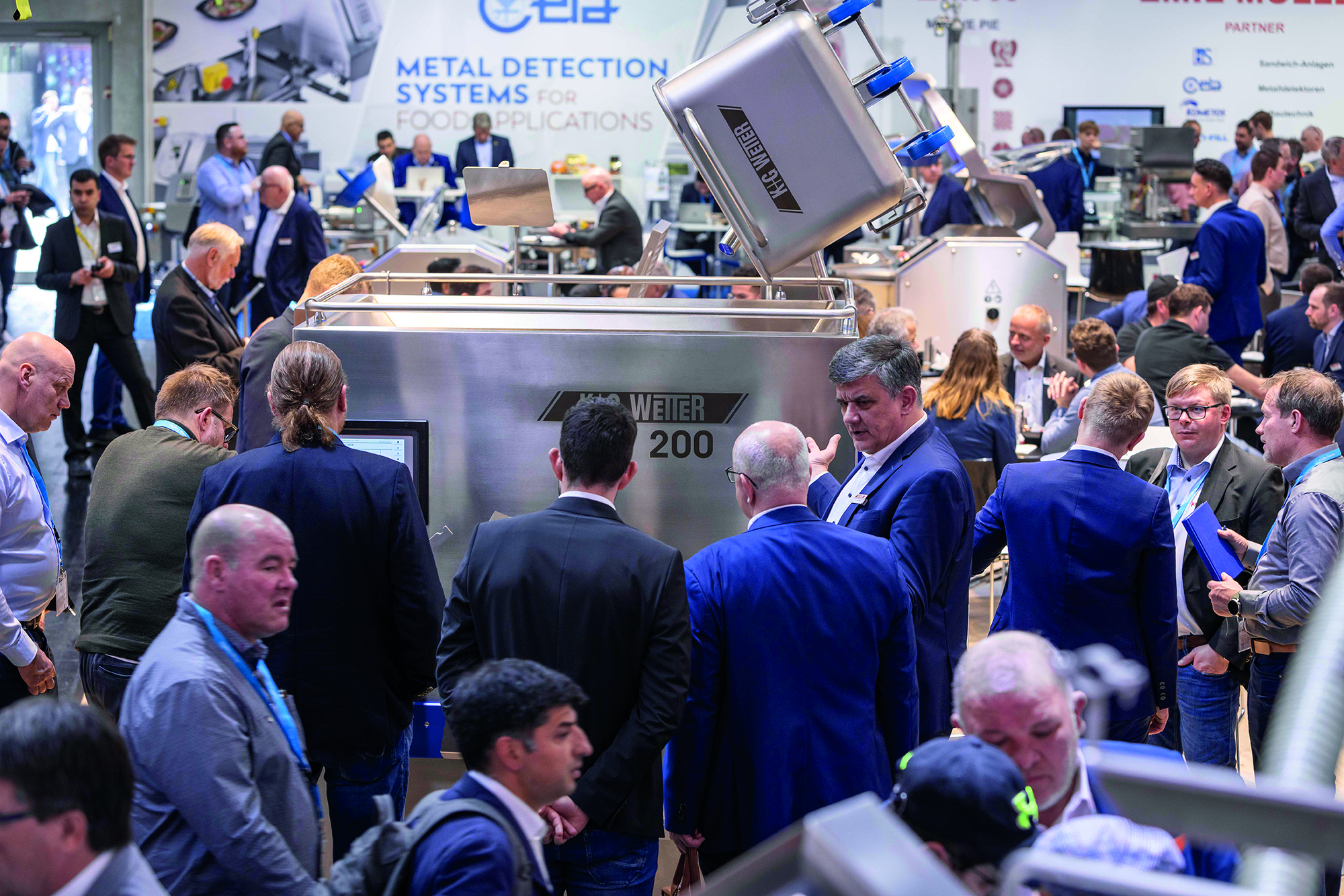

Compact grinders and cutters with great technology for optimal hygiene, user-friendly handling and quality that you can taste, K+G Wetter will be showing at SÜFFA 2024 in Stuttgart (Hall 4, Stand D30).

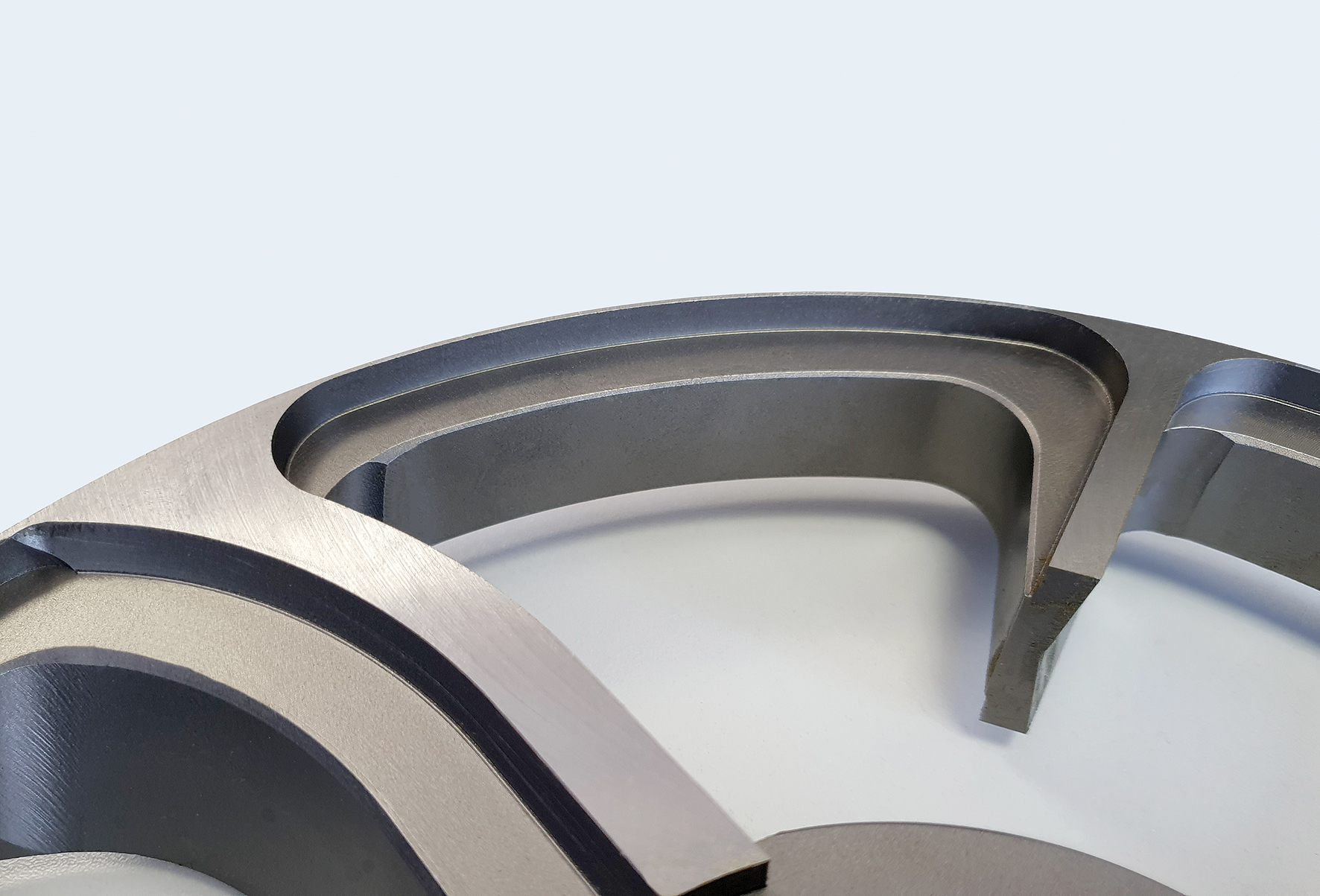

Exclusive ClearCut blade improves performance, consumption and cutting pattern

More processing power, a clearer cut, less energy consumption and wear: with the ClearCut knife, which is available exclusively from K+G Wetter, customers achieve significantly improved, previously unattainable grinding results while also saving on operating costs.

The ClearCut sorting knife: improved product quality without extra effort

With the ClearCut sorting knife, K+G Wetter has once again significantly improved the efficient sorting system of the grinders: unwanted hard parts are reliably removed with almost no meat loss. This prevents product loss and improves quality without additional labour and time.

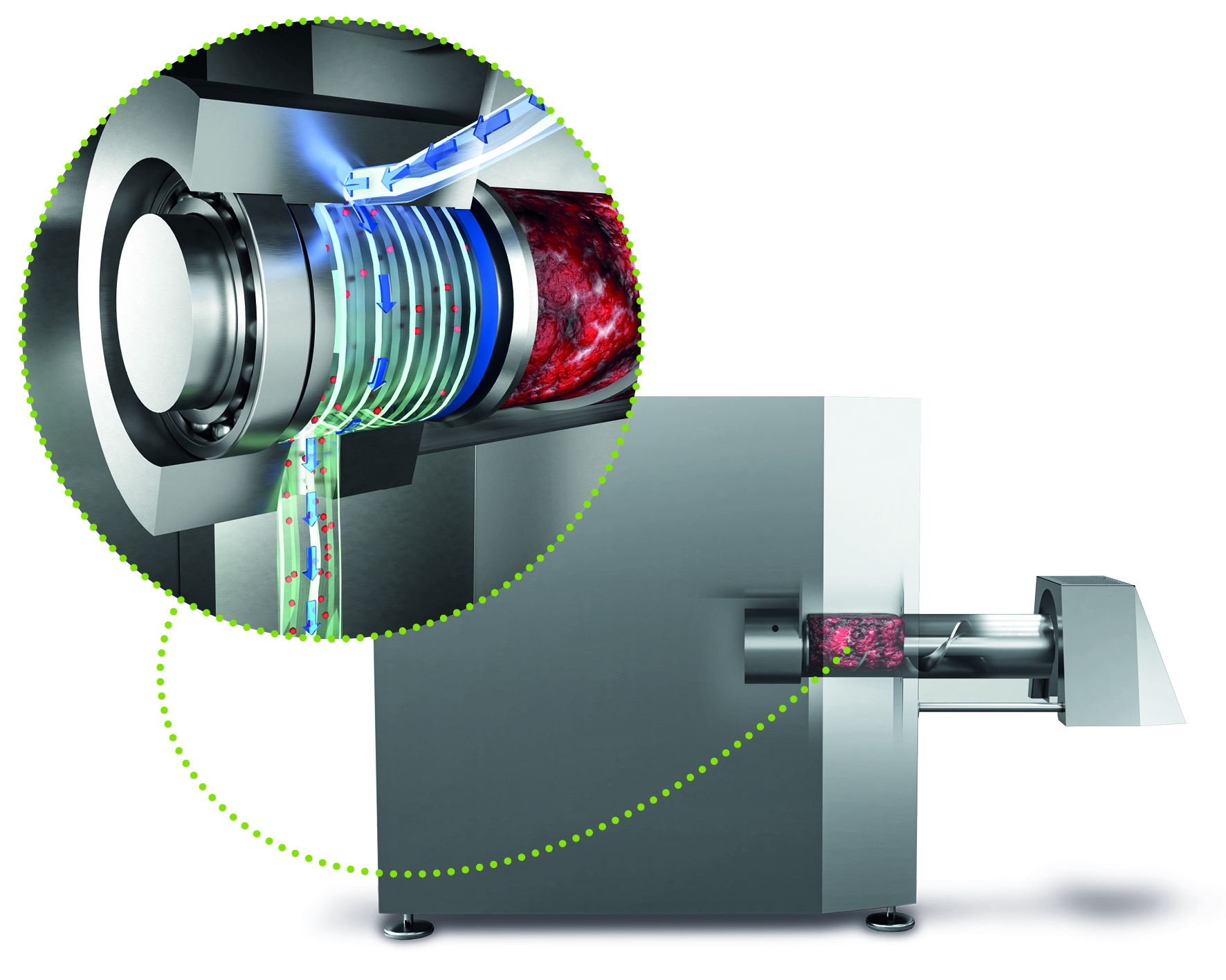

Cleaning chamber for that decisive hygiene plus

The hygiene highlight of the K+G Wetter grinders and mixer grinders is the cleaning chamber. And this is how: The high-pressure during grinding can cause liquids and tiny particles to penetrate the seals of the worms and deposit inside the machine, where they are inaccessible. The cleaning chamber solves this problem by collecting these residues. During daily cleaning, the deposits are simply rinsed out with water and detergent using a hose connected to the outside. Germs don't stand a chance.

Flexible all-rounder for fresh meat and frozen meat blocks

With the new angle grinder WW 200, K+G Wetter makes almost anything possible for medium-sized businesses and industry: powerful and compact, it processes both fresh meat and frozen meat blocks. This makes it unrivalled in terms of flexibility and perfect for companies that work with a mix of fresh and frozen meat.

VCM 70 vacuum cutter for trade butchers completes the Hygienic Secure series

The compact VCM 70 excels in the food trade with its convincing Hygienic Secure features: the patented knife cover strip, which can be easily removed for cleaning, large cleaning flaps and a special sealless design between the vessel and cutter bowl.

Easier, safer, faster cutting thanks to recipe management with CutControl

Customised control software makes many work steps in food processing easier, safer and faster. Many K+G Wetter customers are already convinced by the CutControl recipe management software: once created, employees no longer have to monitor every step of a recipe but can rely on automated cutter control processes. In addition, faulty batches are almost impossible and the quality of the products is reproducible. When batch sizes are changed, the recipe components are automatically recalculated.

SÜFFA 2024: Hall 4, Stand D30

Photos: K+G Wetter

Image 2 and 3: With the newly developed knives in the ClearCut series, the K+G Wetter grinders and mixer grinders achieve results that are more than inspiring and represent a new dimension in grinding: with an even clearer cut and red-white separation.

Image 4: The cleaning chamber makes the crucial difference in terms of hygiene for the grinders and mixer grinders from K+G Wetter. Deposits are collected and rinsed out daily, and the inside of the machine remains completely free of product residues.

Image 5: The new WW 200 for medium-sized and industrial businesses – high performance meets maximum flexibility.

Image 6: The compact VCM 70 vacuum cutter from K+G Wetter impresses with hygiene features that have been convincing customers for years.

Image 7: The CutControl software manages recipes and guides you step by step through the processing programmes – this saves time, prevents errors and ensures consistent product quality.