Focused on quality: new CutCounter for K+G Wetter cutters

Knives are sharpened when they are dull - so far, so simple. Dull knives on artisan or industrial cutters be recognised, for example, by a change in the consistency of the sausage meat, longer processing times or an unwanted increase in the temperature of the sausage meat. By the time it gets to this point, however, the cutter has been working for far too long with wasting time and quality.

A sharp eye: CutCounter monitors knife rotations

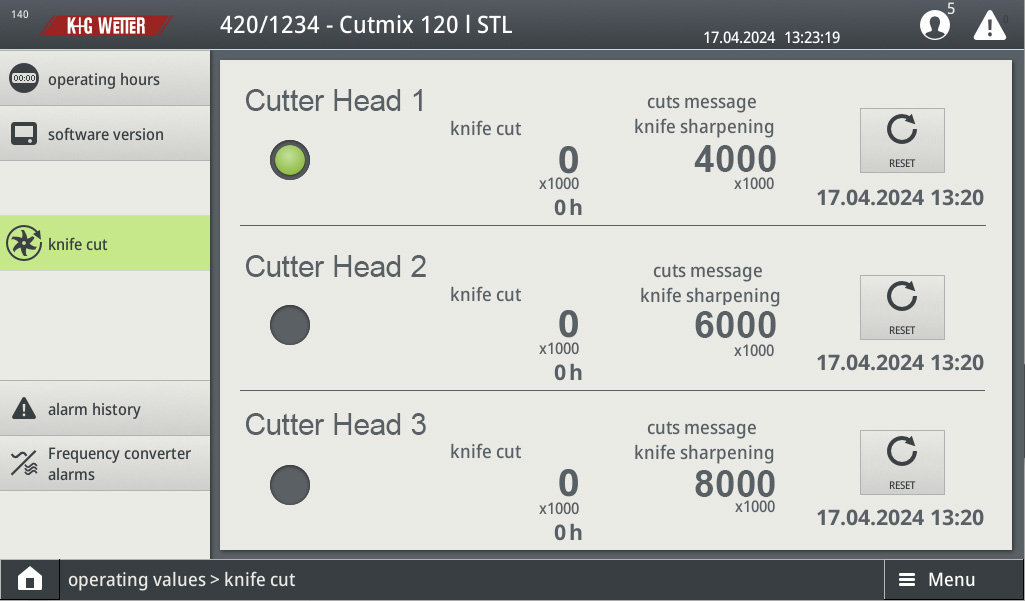

Sharpening the cutter knives therefore must always be kept in mind in the daily production routine of food processing. The solution for cutters from K+G Wetter: the new CutCounter as a smart digital assistant. The optional function, available from the CutMix CM 50 model upwards, keeps a precise eye on the number of cuts made with a set of knives.

Important: the counter is not a separate program, but an option that is activated on the touch panel. CutCounter can be easily upgraded to K+G Wetter cutters and does not require any additional software.

Three individually adjustable sharpening intervals

A total of three different knife sets or three complete cutter heads can be stored in the CutCounter. The total number of rotations after which the CutCounter recommends re-sharpening can be set individually for each. The parameter is entered directly on the intuitive touch panel of the K+G Wetter cutter. And it is also displayed directly on the machine when the knives need sharpening.

A practical solution: CutCounter stores the number of cuts even if the cutter head including knives or just the knives (if only one head is in use) are changed before the maximum number of cuts is reached. This is the case, for example, when switching between cooked and raw sausage meat. When the knives are used again, the system simply resumes counting from the previous position. This means that butchers and machine operators always have an overview of the sharpening intervals, even when changing cutter heads / knives.

Best sausage meat quality, precisely reproducible

"The exact recording of the number of cuts by CutCounter makes it possible to produce top quality products that can be exactly reproduced," says Volker Schlosser, International Sales Manager at K+G Wetter. " Also not to be underestimated is the increased energy consumption when using knives that are not optimally sharpened and the effect on the service life of the knives themselves. These are easily avoidable extra costs."

Sharpening service for precise results

K+G Wetter's in-house sharpening service can regrind and sharpen the cutter knives on request. With its expertise and professional equipment, the service team ensures sharp knives with the right profile for the best products in the shortest possible time.

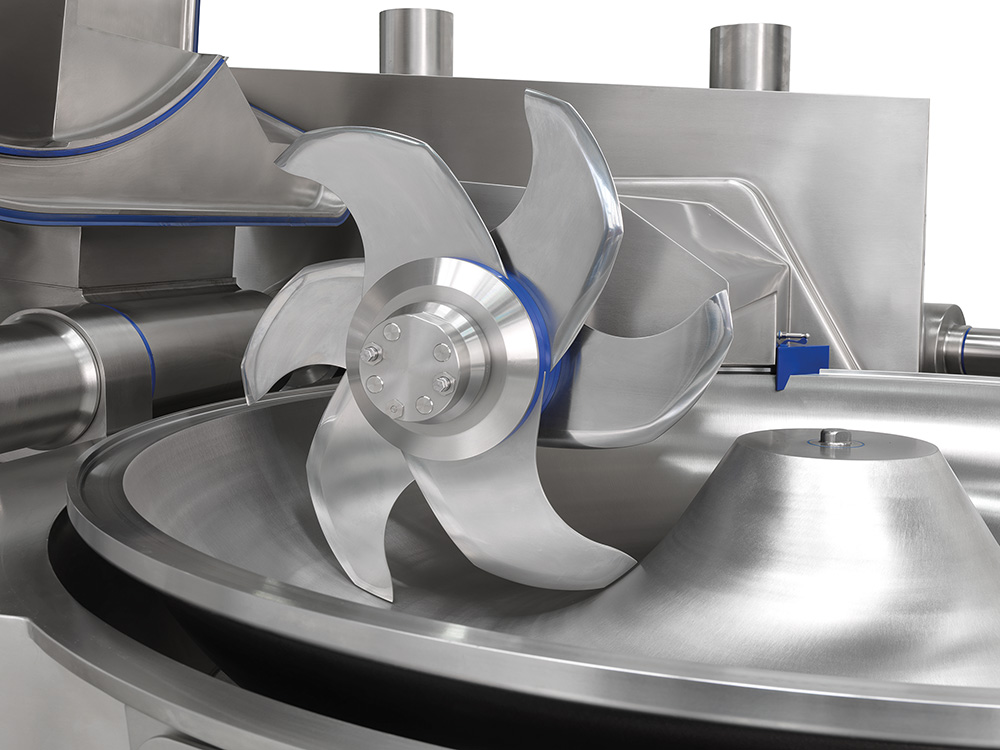

Image 1: The new CutCounter keeps a close eye on the sharpening intervals of K+G Wetter cutters. The sausage meat quality is consistently high and additional costs due to higher energy consumption and wear are avoided.

Image 2 and 3: CutCounter from K+G Wetter is used to enter the number of knife cuts directly on the cutter and to read a note on regrinding.