Certified hygiene

With our advanced bowl cutters, grinders and mixer angle grinders, our specialists have not only incorporated progress into our creations, but also their solutions for hygiene. With the "Hygiene tested" by DGUV Test award, the German Food and Packaging Testing and Certification Body confirms the safe effectiveness of this well thought-out technology.

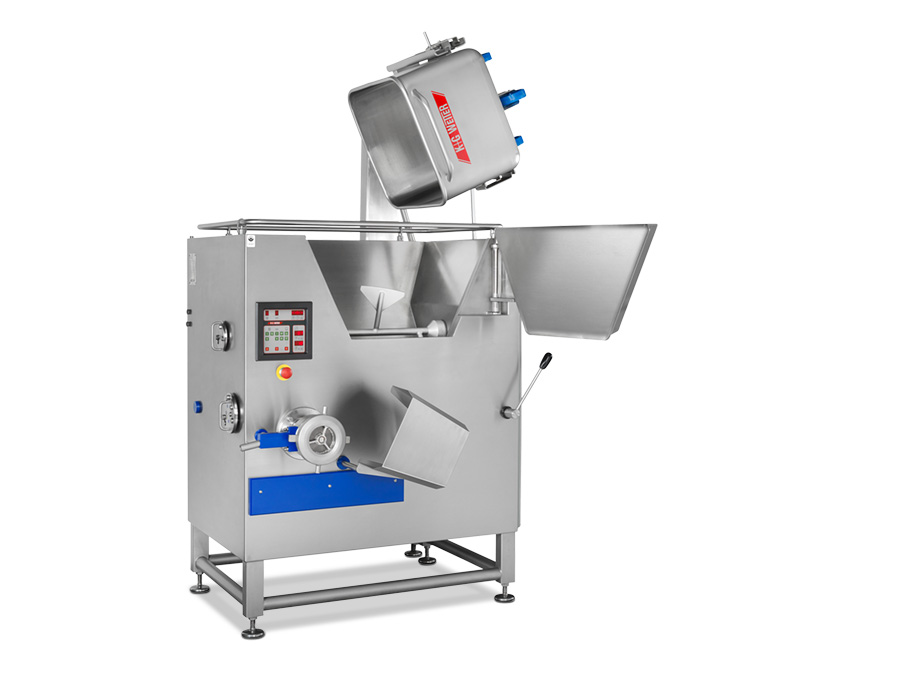

In practical use, for example, the Angle Grinder and Mixer Angle Grinder E 130 / G 160 with "Easy Access" offers a convenient opening for access to the grinder hopper. This not only makes work easier, but also, and above all, makes cleaning easier, thus providing a plus in terms of hygiene. In addition, there is the sorting device, where the manual and the pneumatic device can be completely installed or removed in a few seconds. This enables users to clean the individual components thoroughly and with great ease.

In addition, our grinders and mixer grinders are equipped with cleaning chambers behind each mixing shaft, feeder and a meat worm intake. These ensure that when, for whatever reason, a seal is no longer fully functional, liquids or smaller product components cannot get into the machine body. They are then safely taken into the chambers. These are rinsed during daily cleaning, which only takes a few seconds, and any impurities are removed.

In this way, such incidences first being detected once an odour has developed, by which time it is usually already too late, is avoided. With the K+G Wetter machines there is sufficient time to inspect the seals and replace them if necessary.

Hygiene is also a top priority with the 120 litre vacuum bowl cutter (VCM 120) and our new Vacuum Cutmix industrial bowl cutters VCM 360 and VCM 550 Hygenic Secure. The completely enclosed system ensures product safety, for example. Thanks to the special double wall solution of the cutter bowl, no water or steam reaches the sausage meat. Cleaning is also easy to carry out. With the circumferential distance between bowl and vacuum vessel, there are no more seals and there is no chance for product to be deposited

Another advantage for hygiene: All K+G Wetter machines are hand-polished. Thus the roughness of the surface is extremely minimised. This means that adhesions have less chance of becoming stuck. For us, such hygiene certification is a matter of course. At the same time, of course, we are delighted that our machine solutions have significantly improved hygiene in meat processing.