The Automatic Grinder AW K 280 processes frozen meat blocks with ease

K+G Wetter delivers a powerful solution: The Automatic Grinder AW K 280 processes frozen meat blocks with ease

With the Automatic Grinder AW K 280, K+G Wetter has developed a machine that can process both fresh meat and frozen meat blocks quickly and efficiently. Designed for industrial companies with special requirements, the robust grinder can even provide maximum performance during continuous operation, and effortlessly delivers high output with excellent quality at the same time.

The modern industrial grinder works according to K+G Wetter's reliable two-worm principle. Due to a feeder worm made of special cast iron with a peeler edge, the automatic grinder is particularly efficient and strong. This allows it to cut frozen blocks instead of breaking them. Furthermore, the automatic grinder from K+G Wetter is distinguished by its particularly high hopper volume: With a capacity of 635 litres, it can process up to 22 tonnes of fresh meat per hour at low noise levels, and can also easily shred frozen meat. The capacity for standard blocks (60 x 40 x 25 cm) is 3.5 to 8 t/h, depending on the size of the end-hole plate and product, and even up to 16 t/h for frozen meat that has already been pre-cuted. The result is a clean, clear cut without smearing.

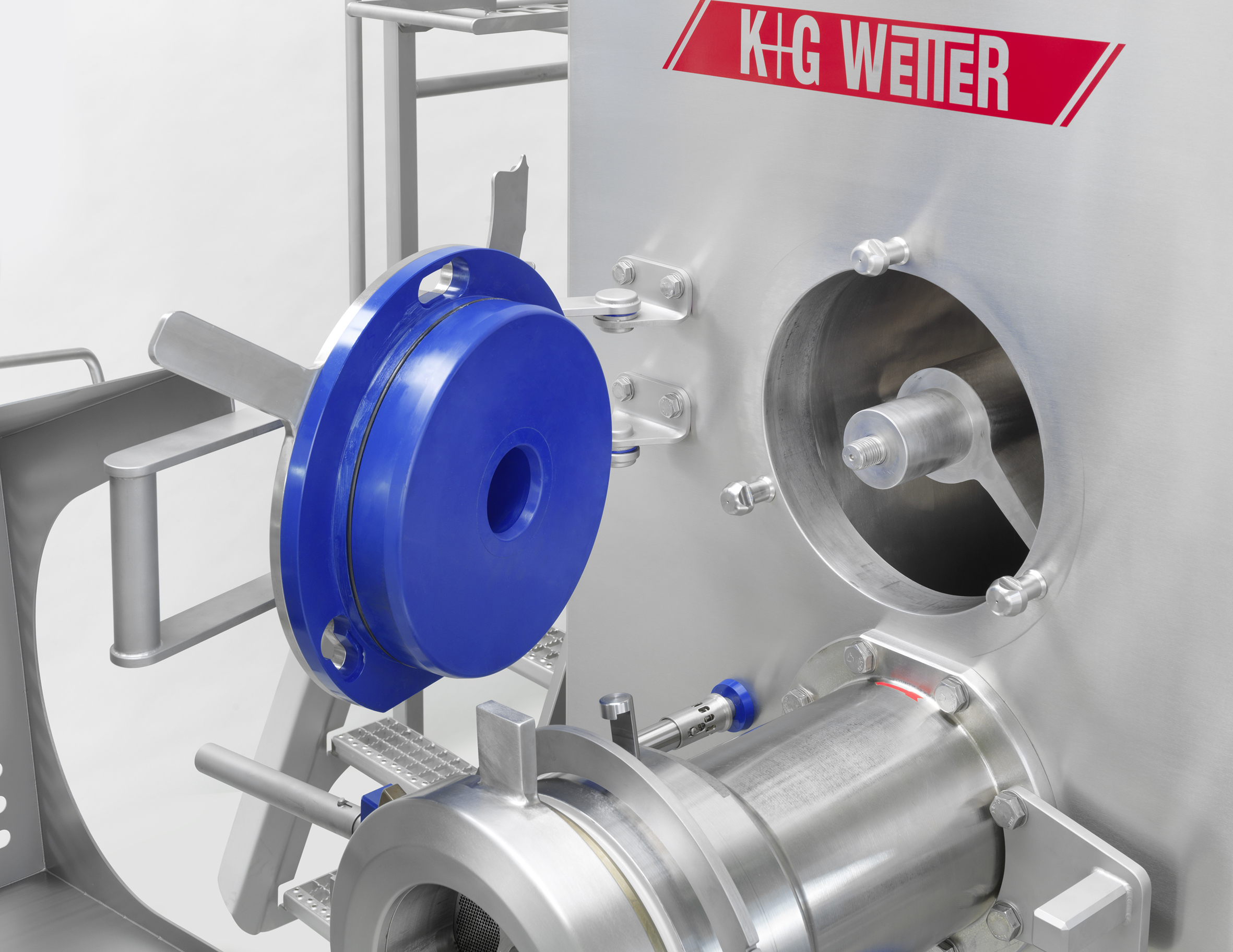

Optimised counter bearing for increased safety

In addition, the industrial grinder scores points with other properties that make work much easier. Innovatively, the machine is equipped with an optimised feeder worm counter bearing, which is now attached to the machine body with hinges. Instead of having to remove the counter bearing, it can thus be easily opened without tools. Another plus in terms of safety: For cleaning, the feeder worm just needs to be pulled forward a few centimetres. An internally installed cleaning nozzle automatically cleans the worm intake. In addition, a special flushing connector allows cleaning inside the machine behind the drive mounts of the meat and feeder worm should products push their way through a seal. This also guarantees optimum safety in terms of hygiene.

The sorting device makes life easy

A pneumatic sorting device is optionally available for the powerful automatic grinder. The K+G solution enables a simpler and faster control of rejected material by discharging the hard parts laterally during the mincing process. In addition, the pneumatic device can be installed and removed in no time at all without tools and can thus be cleaned particularly easily and carefully.

K+G WETTER GmbH

K+G Wetter is a global partner of choice when it comes to manufacturing high-quality, reliable meat-processing machinery. K+G Wetter develops innovative bowl cutters, meat grinders and mixers for butchers and skilled operators engaged in the meat-processing trade. The sophisticated technology and high-quality processing features of K+G Wetter machines play a significant role in bringing about customers’ corporate success. An internationally renowned brand, this company from Biedenkopf-Breidenstein in Hesse (Germany) supports its customers by dispensing personalised and individual advice.