Special sorting knife and innovative knife spigot optimise K+G Wetter grinders

A small piece of bone or gristle can really spoil your enjoyment of a Bolognese or burger. In addition to carefully preparing meat before grinding, butchers can ensure even better quality and customer satisfaction – by using a sorting device to guarantee enhanced product quality. Brand new from K+G Wetter: A special sorting knife, that can only be found in K+G grinders and mixer grinders. A further innovation is the newly developed knife spigot, which is fitted to the machines to ensure improved hygiene, simple and safe cleaning as well as fast and cost-effective replacement when it wears.

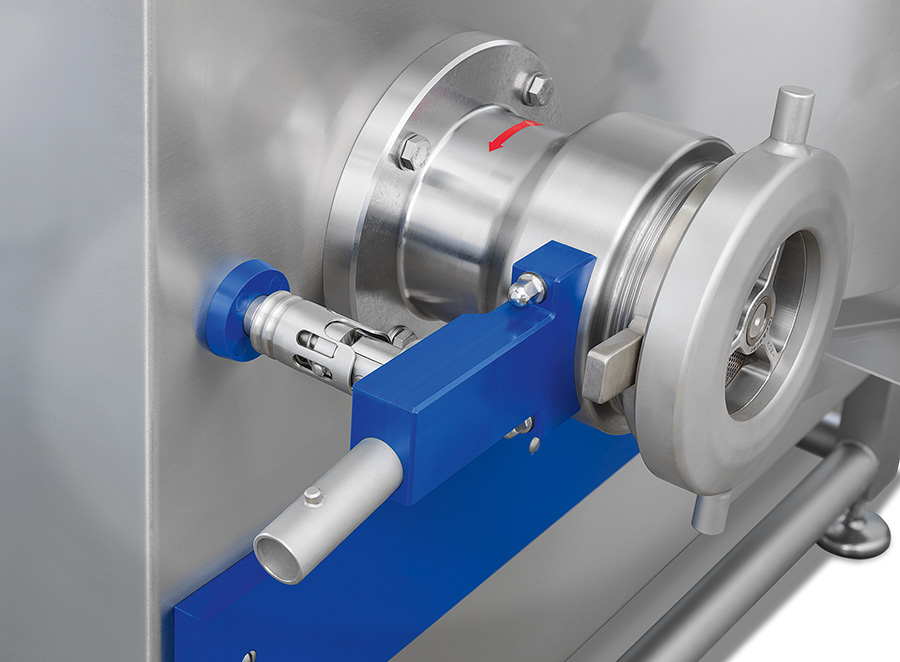

Innovative knife spigot optimises hygiene and machine availability

In grinders and mixer grinders the knife spigot is a highly stressed component which is therefore susceptible to wear. A new development from K+G Wetter now offers a clever solution: The knife spigot now comes with a heavy-duty square push-in connector and the special seal, made of an especially durable material, is pressed into place. It is now possible for the first time to replace the knife spigot, in the event of damage, easily and cost-effectively using standard tools, without having to replace the entire meat worm. The especially smooth surface of the new knife spigot, which has no concealed cavities, facilitates hygienically secure cleaning, improves product safety and saves time.

The K+G Wetter sorting knife

The sorting knife, which has undergone further development and is now available for K+G Wetter grinders and mixer grinders, visibly optimises the cutting pattern thanks to its new cutting geometry. The knife reliably and selectively sorts out the undesirable hard particles such as cartilage, tendons and small bone particles. It is also highly durable and facilitates higher product throughput. It replaces a standard knife in the cutting set, otherwise the normal cutting set components are used. This ensures that the full cross-section of the cutting set is always available to enable the production of high-quality products.

Another special feature of the sorting device in K+G Wetter’s grinders and mixer grinders is that the undesired hard particles are discharged to the side during the grinding process. This allows the working area in front of the machine to remain clear. K+G Wetter offers either a manual or pneumatic drive solution to open and close the lateral discharge aperture, depending on machine size and the customer’s wishes. All components can be stripped down to their individual parts without using tools in just a few simple steps, making them quick and easy to clean in a hygienically secure manner. They can then be reassembled just as quickly, ready for producing the next batch. This minimises set-up times and ensures a more efficient production process.

Animation illustrates the function and benefits of the sorting device

Precisely how the sorting device works is, of course, hidden from view during daily operations, since the sorting knife is situated inside the cutting set housing along with other knives and perforated disks. To clearly illustrate how this clever technical solution works, K+G Wetter has produced a detailed animation that offers viewers a look inside the cutting set during the grinding process.